Thermal technology has made great strides in recent years, transforming the way industrial processes that require heat treatments are managed. The incorporation of automation, remote control, and integration with advanced monitoring systems has improved accuracy, efficiency, and safety in the industry.

What is advanced thermal technology?

Advanced thermal technology refers to the use of intelligent control systems, high-precision sensors, and process automation in heat treatments such as the drying of refractory materials, preheating, or post-weld heat treatment (PWHT).

Key components of advanced thermal technology

- Automated temperature control systems: Allow precise adjustment of thermal conditions in real time.

- High-precision sensors: Used to measure and monitor the temperature of parts accurately, ensuring higher quality in processes.

- Integration with remote monitoring systems: Facilitates process supervision from a distance, improving responsiveness to possible parameter deviations.

Why are automation and remote control essential in heat treatments?

Automation and remote control offer greater consistency and precision, reduce the risk of human error, and increase operational efficiency—crucial aspects when working with materials that require specific thermal conditions.

Benefits of automation in thermal processes

- Improved accuracy: Automated systems ensure that temperature remains within an optimal range, preventing overheating or rapid cooling that could damage parts.

- Real-time monitoring: Remote control systems allow parameters to be monitored and adjusted without the need for physical presence, speeding up processes and improving responsiveness to potential failures.

- Operational efficiency: Automated processes are carried out faster and more continuously, increasing production capacity without compromising quality.

![Thermographic inspection in industrial equipment]() Advanced thermal technology and industrial process safety

Advanced thermal technology and industrial process safety

Safety is one of the fundamental pillars in industrial processes involving high temperatures. Automation and remote control not only improve efficiency but also reduce the risks associated with the direct handling of hazardous or high-temperature materials.

Advantages of advanced thermal technology in terms of safety

- Less human exposure to extreme conditions: Remote control makes it possible to make adjustments without operators being in direct contact with high-temperature equipment.

- Early fault detection: Advanced monitoring systems can detect anomalies in thermal processes before they become serious problems.

- Optimized response times: In the event of a failure or even a slight deviation, automatic systems can immediately correct thermal parameters, preventing damage to parts or equipment.

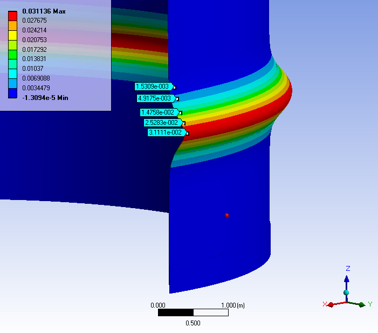

![Thermal simulation of stress in industrial components]() The future of advanced thermal technology

The future of advanced thermal technology

With the integration of artificial intelligence and data analysis, advanced thermal technology will continue to evolve. These innovations will allow real-time process optimization, failure prediction before it occurs, and improved efficiency, taking the industry to new levels of precision and safety.

Advanced thermal technology and industrial process safety

Advanced thermal technology and industrial process safety The future of advanced thermal technology

The future of advanced thermal technology