Post Weld Heat Treatment (PWHT) is an essential technique in industrial manufacturing, ensuring the stability and durability of welds to improve the mechanical properties of components. This process is applied after welding:

- To relieve residual stresses.

- To prevent long-term structural problems.

Why is Post Weld Heat Treatment (PWHT) crucial?

Welding involves intense heating and cooling that generates internal stresses in the material. If these stresses are not properly relieved, they can lead to premature failures, cracking, and loss of mechanical properties.

Benefits of PWHT

- Residual stress reduction: PWHT relieves stresses generated during welding, improving structural integrity.

- Improved ductility and strength: Enhances the material’s ability to withstand deformation without breaking, essential for components under mechanical loads.

- Crack and fracture prevention: Reduces the risk of cracking, especially in materials sensitive to thermal stress.

- Increased corrosion resistance: Particularly in steels, PWHT improves resistance to corrosion after treatment.

How is Post Weld Heat Treatment (PWHT) performed?

PWHT is carried out using different heating methods depending on process needs and material characteristics. The most common methods include:

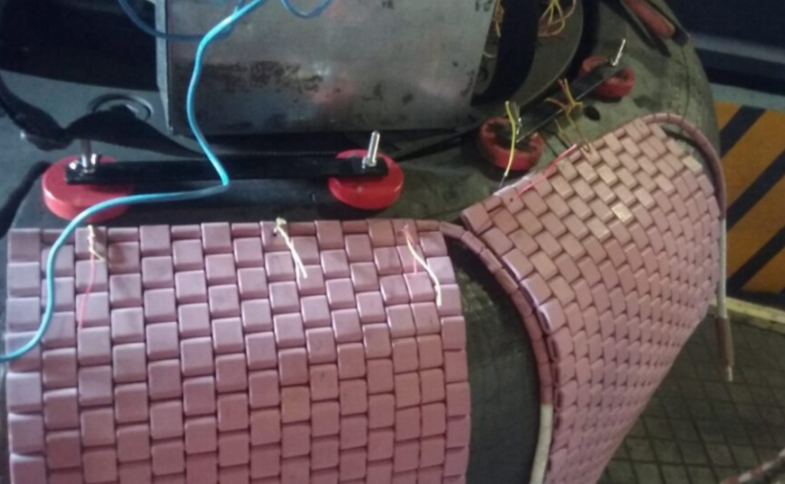

- Electrical methods: Use resistance heating to uniformly heat the component.

- Induction methods: Apply heat via electromagnetic induction, highly effective for large and thick components.

- Combustion methods: Use gas or diesel burners to generate the required heat in large equipment.

![Horno portátil y sistema de control durante tratamiento térmico PWHT en un depósito industrial]() Equipment used in PWHT

Equipment used in PWHT

Intec-Heat employs advanced equipment to perform PWHT with high precision, such as:

- Portable furnaces: Suitable for large equipment like reactors or tanks.

- Three-phase heat treatment machines: Allow precise temperature control and can handle multiple heating circuits simultaneously.

- Temperature recorders: Monitor and log treatment temperatures to ensure correct process execution.

![Aplicación de resistencias flexibles en soldadura industrial para PWHT]() Sectors that benefit from PWHT

Sectors that benefit from PWHT

Post Weld Heat Treatment has critical applications across multiple industries. Some of the most relevant sectors include:

Steel Industry

PWHT is applied to components like ladles and pre-shaped steel parts, improving corrosion resistance and reducing internal stresses.

Energy and Renewables

Essential for large equipment such as reactors and heat exchangers in power plants, where high reliability and structural strength are required.

Offshore and Oil & Gas

Applied to large-scale equipment like columns and storage spheres to ensure resistance to extreme conditions and durability in demanding environments.

Naval Industry

PWHT is crucial in the construction and repair of large ships and submarines, ensuring weld integrity and reliability of critical components.

Equipment used in PWHT

Equipment used in PWHT Sectors that benefit from PWHT

Sectors that benefit from PWHT