At Intec Heat, we specialise in advanced thermal technology solutions, offering customised services to optimise efficiency and safety in industrial processes.

Thermographic Analysis

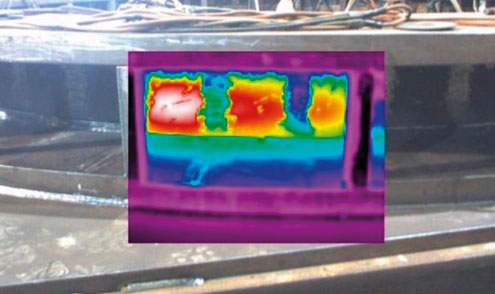

Thermographic analysis is an essential tool in our services. Using high-precision infrared cameras, we detect and visualise temperature distributions in equipment and structures. This technique is crucial for identifying hot spots, heat loss and other problems that can compromise the integrity of equipment. Its applications are diverse, ranging from the inspection of industrial furnaces to the evaluation of thermal insulation systems.

insulation systems.

Thermographic analysis enables early detection of anomalies, reducing downtime and maintenance costs. It also improves energy efficiency by ensuring that systems are operating within optimal parameters.

Our Engineering Department

Our engineering department has state-of-the-art technology and a team of trained experts. We focus on industrial furnace design and heat transfer simulation, ensuring equipment that meets the highest quality standards.

We use Finite Element Analysis (FEA) to predict stresses and deformations during thermal processes. This allows us to optimise the structural design of furnaces, ensuring their reliability and safety under demanding operating conditions.

Innovation and Development

Innovation is at the heart of Intec Heat. We integrate automation and remote control into our thermal processes through PLCs and HMI systems, improving operational efficiency and enabling continuous monitoring. In addition, we develop innovative thermal methods and equipment that respond to changing market needs, ensuring advanced solutions that maximise productivity and minimise risk.