Preheating in welding is essential to prevent defects and ensure the structural integrity of welded joints. At INTEC-HEAT, we use precise temperature control systems and state-of-the-art programmers that maintain a uniform and controlled temperature throughout the piece to be welded. These systems are designed to adapt to different geometries and thicknesses, ensuring flexibility to meet the specific needs of each industry.

High-precision temperature sensors help maintain the established tolerance ranges by automatically adjusting the process to compensate for any deviations. Additionally, our equipment allows for real-time adjustments, optimizing the efficiency and quality of preheating in critical applications, from pipelines to thick components in complex industrial structures.

Detailed Description of Preheating Methods

At INTEC-HEAT, we provide two primary preheating methods, each offering specific advantages tailored to the customer’s needs:

- Electric Resistance Heating:

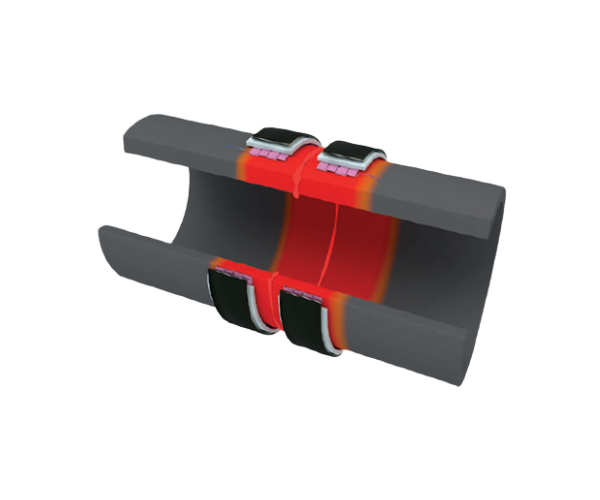

This method enables consistent and controlled heat transfer through electric resistances positioned at a precise distance from the welding area. It is ideal for complex geometries or confined spaces where steady and gradual heat is required. The flexibility of the resistances makes them suitable for custom configurations in elements of various shapes and sizes. - Induction Heating:

Induction preheating employs high-frequency cables that, when wrapped around the element to be welded, induce rapid and uniform heating of the piece. This method is especially advantageous in scenarios requiring fast heating or when preheating is conducted in hard-to-reach areas. Our water-cooled cables ensure safe operation during prolonged use and at high temperatures.

Benefits of Working with INTEC-HEAT

INTEC-HEAT has over 35 years of experience in heat treatments and an international presence, with operational teams in more than 10 countries. Partnering with INTEC-HEAT means relying on a team of experts who provide tailored and customized solutions to meet the specific needs of each project. Moreover, our focus on quality and safety establishes us as a trusted provider for industries requiring precision and strict compliance with international heat treatment standards.

Our remote monitoring and supervision systems enable clients to observe the process in real time and maintain control over every phase. Additionally, we offer comprehensive technical support, ensuring continuous operation and prompt resolution of any issues.

Advanced Technology and Process Safety

Safety and control are core principles in INTEC-HEAT’s processes. Our equipment is equipped with infrared sensors and remote control technologies that allow temperature adjustments and automatic shutdowns in case of unexpected stops. This capability is particularly valuable in sectors where safety is critical, such as offshore installations and refineries.

INTEC-HEAT’s preheating systems also feature automatic shutdown mechanisms that activate upon detecting any deviation from the established parameters. This prevents overheating and ensures the protection of both operators and the entire system.

Technical Details on Preheating

Welding preheating is essential to prevent defects and ensure the structural integrity of welded joints. At INTEC-HEAT, we use precise temperature control systems and state-of-the-art programmers that maintain a uniform and controlled temperature across the entire piece to be welded. These systems are designed to adapt to various geometries and thicknesses, ensuring flexibility to meet the specific needs of each industry.

High-precision temperature sensors ensure that the established tolerance ranges are maintained by automatically adjusting the process to compensate for any deviations. Additionally, our equipment allows for real-time adjustments, optimizing the efficiency and quality of preheating in critical applications, ranging from pipelines to thick components in complex industrial structures.

Detailed Description of Preheating Methods

At INTEC-HEAT, we offer two main preheating methods, each with specific advantages tailored to meet our clients’ needs:

- Electric Resistance Heating:

This method provides consistent and controlled heat transfer through electric resistances positioned at a precise distance from the welding zone. It is ideal for complex geometries or confined spaces where constant and gradual heat is required. The flexibility of the resistances makes them suitable for special configurations in elements of various shapes and sizes. - Induction Heating:

Induction preheating uses high-frequency cables that, when wrapped around the element to be welded, induce rapid and uniform heating of the piece. This method is particularly beneficial for applications requiring quick heating or when preheating is performed in hard-to-reach areas. Our water-cooled cables ensure process safety during prolonged use and under high-temperature conditions.

Benefits of Working with INTEC-HEAT

INTEC-HEAT brings over 35 years of experience in heat treatment and boasts an international presence, with operational teams in more than 10 countries. Working with INTEC-HEAT means partnering with a team of experts who deliver tailored, customized solutions for each project’s specific needs. Our commitment to quality and safety positions us as a trusted provider for industries that demand precision and strict compliance with international heat treatment standards.

Our remote monitoring and supervision systems allow clients to observe the process in real time and maintain control over every phase. Additionally, we provide comprehensive technical support, ensuring continuous operation and the prompt resolution of any issues.

Advanced Technology and Process Safety

Safety and control are fundamental pillars of INTEC-HEAT’s processes. Our equipment is equipped with infrared sensors and remote control technologies that enable temperature adjustments and automatic shutdowns in the event of unexpected stops. This capability is particularly valuable in sectors where safety is critical, such as offshore facilities and refineries.

INTEC-HEAT’s preheating systems are also equipped with automatic shutdown mechanisms that activate when any deviation from the established parameters is detected. This prevents overheating and ensures the protection of both the operators and the equipment as a whole.

Sustainability and Energy Efficiency

At INTEC-HEAT, we are committed to sustainability. Our preheating methods are designed to minimize energy consumption by employing high-efficiency equipment and process optimization techniques. For instance, using induction for preheating enables more direct and rapid heat transfer, significantly reducing the time and energy required compared to conventional methods.

Furthermore, by preventing defects and optimizing the lifecycle of treated components, we help reduce waste and maintenance needs in high-demand applications. This translates into benefits not only for our clients but also for the environment, by lowering emissions and minimizing energy waste