Sudden temperature changes are often one of the frequent causes of the alteration of metal properties. For us, understanding this phenomenon has become a key step to maintaining safety and efficiency in our clients’ industrial facilities.

Why do temperature changes affect metals so much?

Metals expand or contract when temperatures change, which can create structural problems if not properly managed.

Thermal expansion and contraction: the starting point

Metals naturally react to heat and cold:

- When heated: they expand, which can cause deformations if they are rigidly fixed.

- When cooled: they contract, generating internal stresses or cracks.

What problems can this effect cause in industry?

In industrial contexts, these changes can cause:

- Cracks in welds or mechanical joints.

- Loss of tightness in pressure equipment.

- Failures in components subjected to repeated thermal cycles.

- Alteration of the mechanical properties of parts.

Which metals are more sensitive to thermal shocks?

As you might expect, not all metals behave the same. Sensitivity to thermal shock depends on their composition and internal structure.

Most vulnerable metals

- Cast iron: very sensitive to thermal shock; can fracture easily.

- Carbon steel: develops internal stresses if not properly treated.

- Aluminum: good thermal conductivity but low resistance to sudden changes.

And the most resistant?

- Stainless steel: more stable against thermal changes, although it requires prior treatments.

- Special alloys (nickel, chromium…): designed to withstand extreme conditions without deforming.

How to prevent failures from thermal stress in industrial facilities?

Preventing these effects is essential to extend the service life of equipment and avoid unwanted shutdowns. Therefore, at Intec-Heat we follow a series of best practices to achieve this:

Recommended best practices

1. Temperature control in critical processes

Use real-time monitoring systems to avoid overheating or rapid cooling.

2. Apply controlled thermal cycles

In phases such as start-up or shutdown of equipment, it is crucial to carry out gradual heating and cooling.

3. Use of proper heat treatments

In certain parts or structures, well-applied heat treatments help release internal stresses and stabilize the material.

Which industrial sectors should pay more attention to these phenomena?

There are industries especially sensitive to thermal changes due to extreme working conditions.

Sectors with greater thermal demands

- Oil & Gas: large thermal variations occur in pressure equipment.

- Naval: constant exposure to marine environments and temperature changes.

- Aerospace: metallic parts are subjected to strong stresses due to heat and altitude.

- Renewable energy: in solar thermal and biomass plants, materials work at high temperatures.

- Cement and steelmaking: involve continuous heating and cooling processes.

What technologies help reduce the thermal impact on metals?

Innovation in thermal engineering has advanced greatly in recent years to help industries better manage these effects.

Current solutions

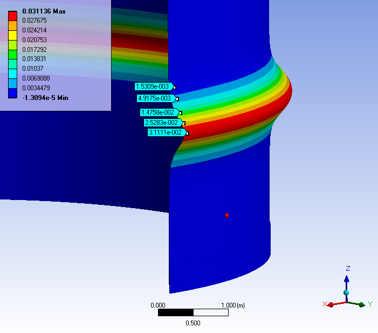

- Finite element thermal simulation: allows prediction of how a component will behave under temperature changes.

- Advanced thermal instrumentation: such as thermocouples, digital recorders, and automatic controllers.

- Electrical and internal combustion heating systems: to apply temperatures evenly and in a controlled manner.