They are the most widely used sensors in these environments, as they allow accurate and real-time measurement of how the applied heat evolves on materials during operations such as Post-welding or Pre Heating of Welding. We discuss them in our new article.

What is a thermocouple and how does it work?

A thermocouple is a sensor that measures temperature through the voltage difference between two different metals joined at one point. When this junction is heated, it generates an electrical signal proportional to the temperature reached.

Main characteristics of a thermocouple

- They are durable and reliable sensors in extreme environments.

- They can measure temperatures from -200 °C up to over 1,300 °C, depending on the type.

- They offer a fast response, ideal for dynamic processes.

Why are thermocouples used in heat treatments?

In processes such as preheating, refractory drying, induction treatments, or heat treatment of pressure vessels, precise temperature measurement ensures that the material reaches and maintains the required conditions to prevent defects.

Benefits of using thermocouples in industry

- Precision in control: They ensure that heat is applied evenly and consistently.

- Process safety: They detect temperature deviations that could compromise the treated structure.

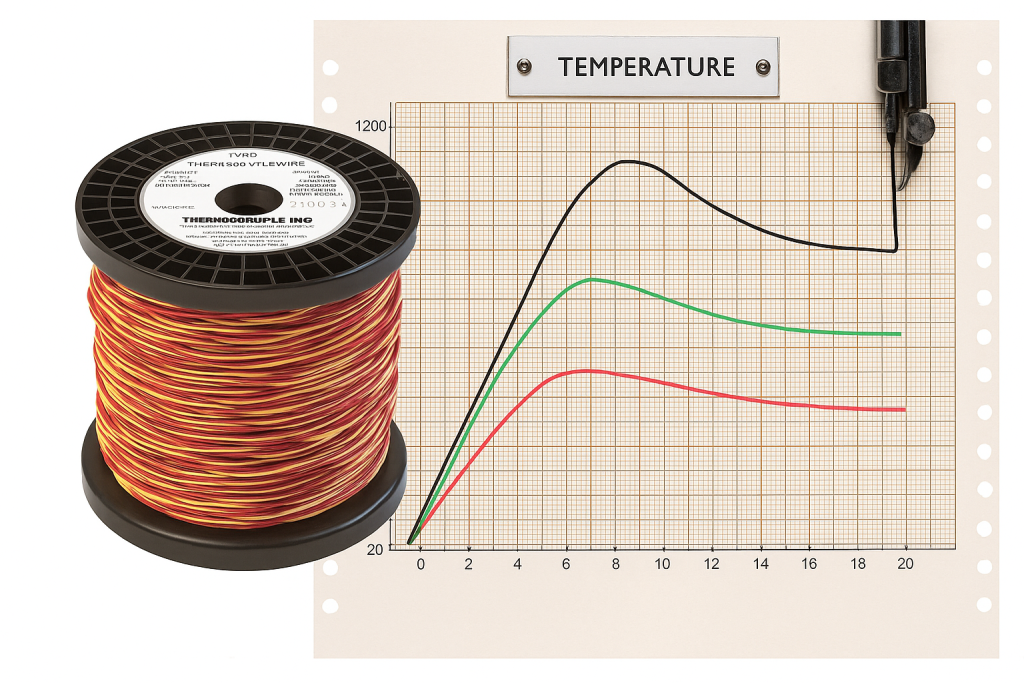

- Traceability: Thermocouple data is recorded in charts that verify the process has been carried out correctly.

![Temperature recorder with thermocouples]() Most common types of thermocouples in industry

Most common types of thermocouples in industry

There are different types of thermocouples, each with a specific temperature range and application. In the heat treatment industry, the most common and widely used by INTEC-HEAT is the Type K (NiCr/NiAl), although other types are used depending on working conditions.

Type K thermocouple

- Working range: up to 1,260 °C in continuous use.

- Suitable for oxidizing and inert atmospheres.

Other types used

- Type J: useful in reducing atmospheres. Measures up to 750 °C.

- Type N: more stable at high temperatures and resistant to oxidation.

How are thermocouples fixed during a heat treatment?

Proper placement of thermocouples is essential. In many cases, capacitive welding equipment is used to attach them directly onto the metal surface. This ensures that the sensor is in full contact with the piece and provides an accurate reading.

If a thermocouple loses contact, temperature recorders immediately detect it and indicate it as an open circuit, allowing the issue to be corrected quickly.

Applications in industrial sectors

The use of thermocouples is not limited to a single sector. They are used in a wide range of environments where temperature control is critical for equipment safety and reliability.

- Offshore Wind Jackets and Jacket Offshore preheating: in the construction of marine and wind structures, thermocouples allow precise monitoring of heating processes on large metal joints.

- Heat treatment of pressure vessels: ensures that the structure withstands extreme conditions without failure.

- Induction treatments: used on components where heat must be concentrated in very specific areas, always with high-precision sensor control.

Thermocouples are the foundation of control in industrial heat treatment processes. Thanks to them, it is possible to apply heat safely, accurately, and with full traceability — whether in Post-welding processes, induction treatments, the preheating of Offshore Wind Jackets, or the heat treatment of pressure vessels. Without this control, treatments would lack reliability and could compromise both material quality and installation safety.

Most common types of thermocouples in industry

Most common types of thermocouples in industry