CAPACITY AND FLEXIBILITY

CAPACITY AND FLEXIBILITY

COMPANY

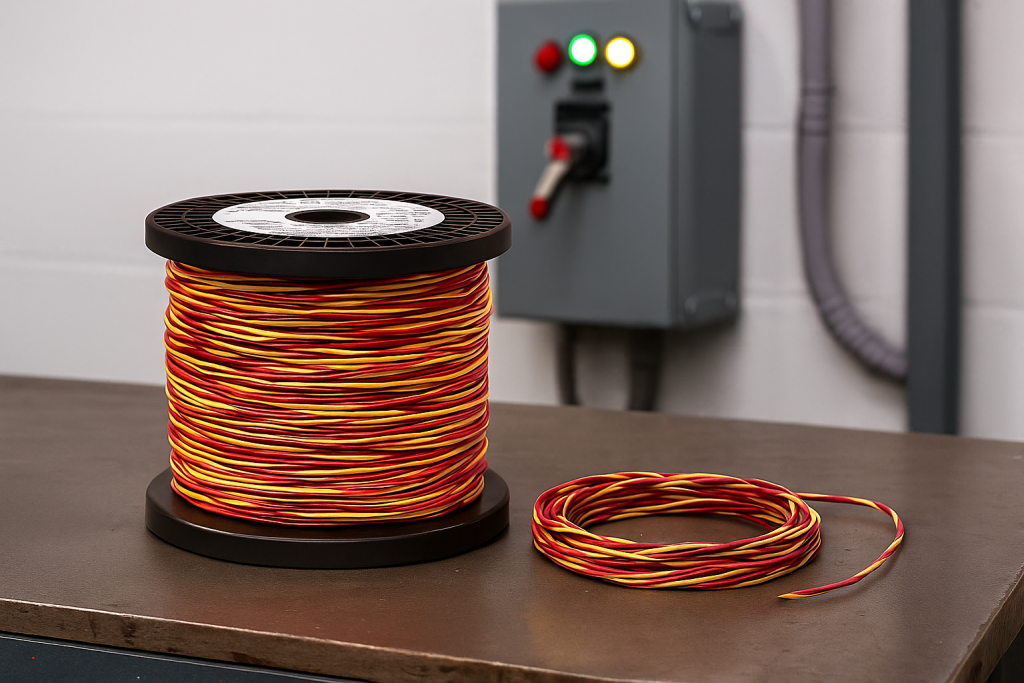

Intec-Heat is a leading heat treatment company, with over 35 years of experience in refractory dry-out, preheating, and post weld heat treatment.

35 YEARS

OF EXPERIENCE

RECURRING

CLIENTS

INTERNATIONAL

CLIENTS

HEAT TREATMENT MACHINES WORKING AT ONCE

OVER 35 YEARS

OFFERING HEAT TREATMENT

Intec-Heat has stayed true to its calling as a services and training company using its own technology. The company stands out for its high productive capacity and highly qualified personnel, working with over 150 pieces of heat treatment equipment.

Our main objective is to develop specific and innovative solutions for each client in a safe and fully satisfactory way.

HOME OF THE HEAT

SERVICES

HEALTH AND SAFETY

It is essential for all tasks to be carried out in an environment with optimal health and safety conditions. As a company, we are committed to continually improving the quality of our services and our working conditions.

INTERNATIONAL PRESENCE